142 Mechanical Shock Techniques

Applications The effects of shock are important in many engineering applications ranging from appliances to computers to ships to automobiles, trucks and military vehicles to high-performance aircraft and missiles. Shock is often part of the service and/or transportation environment. Military Standards such as MIL-STD-810 call for shock testing.

The possible effect of shock must be considered for almost every product that has to be shipped and handled. Care can be taken in a controlled environment but during the transportation phase the product within its package must be designed and tested to withstand the anticipated environment.

The possible effect of shock must be considered for almost every product that has to be shipped and handled. Care can be taken in a controlled environment but during the transportation phase the product within its package must be designed and tested to withstand the anticipated environment.

For Whom Intended Most engineers need specialized education in order to properly measure, quantize and analyze this generally unfamiliar environment, and to reproduce it in environmental test laboratories. This course is for packaging designers, test laboratory managers, engineers and aides. It also helps quality and reliability specialists and acquisition personnel in government and military activities, and their contractors.

Instrumentation specialists who will measure transportation, service and laboratory shock need this course. Metrologists learn about shock calibration of accelerometers and systems. Project personnel, structure and packaging engineers learn about developmental shock testing. Product assurance and acquisition specialists learn to evaluate shock test facilities and methods, and to interpret shock test specifications.

This course is designed to serve the varied needs of scientists, engineers, aides and senior technicians. The instructor maintains good balance between practical training and theory.

Brief Course Description The course commences with a review of basic dynamic theory and then covers natural frequencies and modes before discussing some essentials of signal processing. The discussion of shock starts with terms and definitions, causes and effects of shock and shock pulse shapes. The Shock Response Spectrum (SRS) is discussed as it relates to shock measurement and testing, as well as design. Shock instrumentation and measurements are covered next, with a brief look at calibration. The relative merits of various types of shakers and shock test machines are briefly considered before covering various shock test methods, including pyrotechnic shock testing. The course then covers hock resistant design is discussed, including the selection and use of isolators.

Package and product fragility analysis are covered next, including the use of the damage boundary plot. Some typical shock test procedures and specifications are described, both military and commercial. Classroom (bring calculators) and nightly review problems measure progress.

Bonus Chapter Chapter 10 "Typical Shock Test Specifications" is shown in the course outline below, but it is not presented in the classroom, and it is not included in the Complete Video Course. However, it is provided in the course materials for self-study by interested students, and may be included in on-site presentations at the client's request.

Diploma Programs This course is required for TTi’s Dynamic Test Specialist (DTS) Diploma. It may be used as an optional course for any of TTi’s Specialist Diploma programs.

Related Courses See course 142-4, Mechanical Shock and Modal Test Techniques.

Prerequisites Prior participation in TTi’s Fundamentals of Vibration would be helpful. Participants will need first-year college mathematics (or equivalent experience) and some facility with fundamental engineering computations. Some familiarity with electrical and mechanical measurements and vibration will be helpful.

Text Each student will receive 180 days access to the on-line electronic course workbook. Renewals and printed textbooks are available for an additional fee.

Course Hours, Certificate and CEUs Class hours/days for on-site courses can vary from 14-35 hours over 2-5 days as requested by our clients. Upon successful course completion, each participant receives a certificate of completion and one Continuing Education Unit (CEU) for every ten class hours.

ON-DEMAND OnDemand Internet Complete Course 142 features thirteen hours of video as well as more in-depth reading material. All chapters of course 142 are also available as OnDemand Internet Short Topics. See the course outline below for details.

Course Outline

Chapter 1 - Single-Degree-of-Freedom and 2-Degree-of-Freedom (SDoF and 2DoF) Systems

- The Single Degree Of Freedom System

- The Spring, k

- The Mass, m

- The Damper, c

- Motion of an SDoF System

- The Impulse Response Function, h(t)

- The Frequency Response Function (FRF)

- Displaying the FRF

- Structural Dynamic Relationships

- Receptance, Mobility, Accelerance

- Two Degrees of Freedom (2DoF)

- 2DoF Example

- The 2DoF Frequency Response Function

- Observations from the 2DoF FRF

Chapter 2 - Multiple-Degrees of Freedom (MDoF) Systems

- The Multiple Degrees Of Freedom System (MDoF)

- Mass Matrix, [M]

- Stiffness Matrix, [K]

- Flexibility Matrix, [H]

- Damping Matrix, [C]

- Natural Frequencies and Mode Shapes

- Modal and Frequency Matrices

- Orthogonality and Normalization

- Decoupling the Equations

- Single Point Excitation and Response

- Observations

- Mode Shapes

- Mode Shapes for a Cantilever

- Mode Shapes for a Plate

- Mode Shape Animation

Chapter 3 - Some Essentials of Signal Processing

- Analog to Digital (A-D) Conversion

- Aliasing

- Avoiding Aliasing

- Fourier Transforms

- Fast Fourier Transform

- Discrete Fourier Transform, DFT

- Windowing

- Windowing for Continuous, Random Signals

- Windowing for Transient, Impulsive Signals

- System Identification Using the FFT

- Signal Averaging

- Coherence

- Coherence—What’s Good and What’s Bad?

- Some (Almost) Unbreakable Rules of Signal Processing

Chapter 4 - Introduction to Shock

- What is Shock?

- Causes of Shock

- Effects and Remedies of Shock

Chapter 5 - A Closer Look at Shock

- Terms Used in Mechanical Shock

- Input Pulse and Response of a Sprung Mass

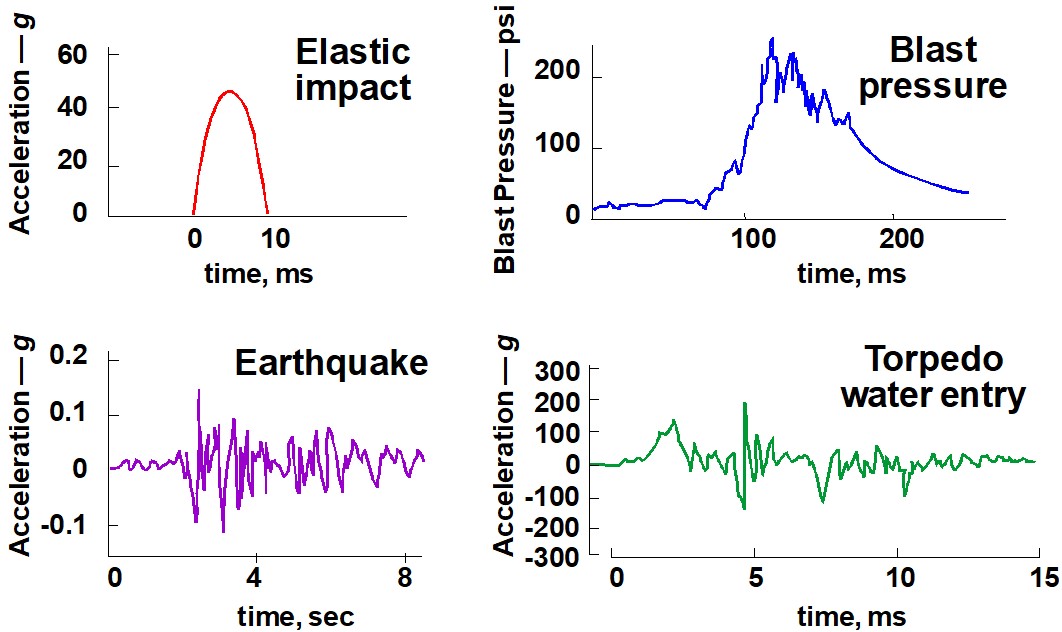

- Typical Complex Shock Pulses

- Shock Pulse Shapes

- Shock Pulse Shape Parameters—Haversine Shape

- Classical Shock Pulse Shapes

- Example of 1000 g 1 ms Shock Pulse—Haversine Shape

- Critical Frequency Response

- Response to Shock Pulse

Chapter 6 - The Shock Response Spectrum

- Shock Response Spectrum (SRS)

- SRS Mechanical Analog

- Accepted Definition of SRS

- Terms used in SRS Analysis

- Developing SRS

- SRS Maximax Values

- Maximum Response Spectra for Various Shock Pulse Shapes

- Some Properties of the SRS

- Velocity Sensitive Region of SRS

- Damping and SRS

- SRS—Damped Spectra

- Maximum Response Spectra for Linear SDoF System

- Designing with SRS

- Absolute and Relative Deflection SRS

- The Use of the SRS in Shock Testing

- Required Spectrum and Allowable Tolerances

- Shock Specifications

- Shock Spectrum Analyzers

- Measuring and Analyzing Mechanical Shock

- Subroutine for the Calculation of the SRS

Chapter 7 - Measurement of Shock

- Force Sensors

- Load Cell Characteristics

- Motion—Displacement Trackers

- Characteristics of Motion Trackers

- High Speed Photography

- Electro-Magnetic Induction

- Motion—Velocity Sensors

- Motion—Acceleration

- Seismic Transducers

- Seismic Transducer Characteristics

- Pendulum Calibration

- Dynamic Calibration of Motion Sensors

- Cabling

- Accelerator Attachment

- Accelerometer Quick-Check Calibration

- Accelerometer Loading Effect

Chapter 8 - Shock Testing

- Types of Mechanical Shock Testing

- Impulse Shock Test

- Shock Pulse — Acceleration, Velocity and Displacement

- Example

- Drop Test Machines

- Navy Impact Machines

- The “Light-Weight” Shock Tester

- High-Amplitude, High-Frequency “Impact” Transient Simulators

- Impact Shock Simulators

- MIPS Table .. Closer Look

- Programmable Systems

- Moderate-Level and/or Mid-Frequency Transients

- Electrodynamic Shakers

- Electrohydraulic (EH) Shakers

- Piezoelectric Shakers

- Shaker Technologies—Stroke vs. Frequency Range

- Electrodynamic and Electrohydraulic Exciters

- Optimized Tailoring

- Generation of Oscillatory Transients

- Decaying Oscillatory Acceleration

- Shaker Optimized Cosine (SHOC) Pulses

- Least Favorable Response

- Pyrotechnic Shock

- Simulating the Damage from a PyroShock “Event”

- Rupture Energy Fixture

- More Realistic Pyroshock Arrangements

- Shock Testing Problem Areas

- Data As We See It.

- What Our System Has To Handle

- Drop Machines

- Objectives

- Pendulum Type Shock Machine

- Free-Fall Shock Machine

- Drop Testing Machine

Chapter 9 - Design to Withstand Shock

- Shock Resistant Design

- Shock Isolation

- Shock Isolation vs. Vibration Isolation~

- Isolators Which Approach the Ideal

- Shock Isolation Example

- Protective Packaging

- Potentially Harmful Environments

- Drop Height vs. Probability

- Product Fragility

- Damage Boundary Theory

- Step Velocity and Step Acceleration

- The Step Acceleration Test

- Damage Boundary Plot

Chapter 10A - MIL-STD-810G, Method 516.6, Shock (optional)

Chapter 10B - Undex Underwater Explosions And Surface Testing (optional)

Chapter 10C - Typical Free Fall Shock Test Specification (optional)

- Free Fall Drop Test Methods

- Tabulation of Test Data

- Test Procedures, under 55 lbs.

- Test Procedures, under 220 lbs.

- Test Procedures, 220–1,000 lbs

- Surface Drop Test

- Edge Drop Test

- Corner drop tests

- Equipment Handling

- Test Set-up Using a Mechanical Device

Chapter 10D - Table-Top Drop Shock Test (optional)

Chapter 10E - Typical Drop Shock and Vibration Test Specification for Disk Drive Assemblies (optional)

- Purpose

- Associated Documents

- Equipment Required

- Software

- Drive Configuration

- Drop Shock Fixturing

- Design Verification Testing

- Design Maturity Testing (DMT)

- Disk Device Shock/Vibration Specification

- PCB Shock/Vibration Specification

- Pneumatic Drop Test Shock Machine

- Orientation of Axes

- Drop Shock Test Fixture

- Drop Shock Test Fixture Adapter to Shock Table

- Typical Drop Shock Pulse