471 Cooling Methods for Electronics Design

(formerly Course 236)

For whom intended Electronic designers and packaging specialists, environmental test laboratory engineers and technicians, specification writers, equipment designers, and quality and reliability specialists.

Brief Course Description The course introduces the fundamentals and physics of thermodynamics and heat transfer. It then shows how to apply this information to the design and testing of electronic and other hardware. Since conventional methods of electronics cooling may not meet the demands of new advanced designs, the instructor will discuss some advanced cooling techniques, some of which will set new industry standards in the 21st century. A class project is included to provide supervised practice in using the course material.

The course is presented as a series of highly-interactive lecture/discussion sessions. Problems for individual and group solution are interspersed throughout the course to act as training aids and to evaluate class progress. Special-interest discussions are encouraged outside of the regular course sessions. Student comments on this course are very positive.

The course is presented as a series of highly-interactive lecture/discussion sessions. Problems for individual and group solution are interspersed throughout the course to act as training aids and to evaluate class progress. Special-interest discussions are encouraged outside of the regular course sessions. Student comments on this course are very positive.

Diploma programs This course is required for TTi’s Electronic Design Specialist (EDS) Diploma Program. It is an optional course for any other TTi specialist diploma program.

Prerequisites There are no definite prerequisites. However, this course is aimed toward individuals involved in related technical fields.

Text Each student will receive 180 days access to the on-line electronic course workbook. Renewals and printed textbooks are available for an additional fee.

Internet Complete Course 471 features over 15 hours of video as well as more in-depth reading material. All chapters of course 471 are also available as OnDemand Internet Short Topics. See the course outline below for details.

Course Hours, Certificate and CEUs On-site courses can vary from 14-35 hours over 2-5 days as requested by our clients. Upon successful course completion, each participant receives a certificate of completion and one Continuing Education Unit (CEU) for every ten class hours.

Click for a printable course outline (pdf).

Course Outline

Chapter 1a - Introduction

- The Need for Thermal Management of Electronics

- Effects of temperature on electronic components

- Junction temperature of an IC

- Trends in thermal variables, industry trends

Chapter 1b - Basics of Heat Transfer, Electronic Cooling, and Thermal Design

- Definitions, temperature scales

- Basic thermodynamics, heat transfer mechanisms

-

Thermal Design Process

- The Influence of Thermophysics on the Design of Electronic Equipment

Chapter 2 - Conservation of Energy

- First Law of Thermodynamics

- Conservation of Energy

-

Energy Balance

- Controlled Mass System, Examples

- Controlled Volume System, Examples

Chapter 3 - Conduction Heat Transfer

- Heat flows through a solid

- Addition of Thermal Resistances

- Series

- Parallel

- Combination

- Factors affecting Joint Thermal Resistance

- Roughness

- Pressure

- Improving conduction: Metal foils, shims, thermal grease,

- Effect of contact pressure and area

- Contact resistance, minimizing; Example

- Heat Sinks and Heat Exchangers

- Properties of Thermal Plane Materials

- Thermal wedge clamp; Example

- Surface Mount PC Board Assembly

- Metal core PC boards; materials; determining IC case to board core resistance

- Thermal paths, thru-hole vias

- Amplifier internal heat sinking

- Thermal conductivity of

- Substrate materials

- IC packaging materials

- Adhesives

- Thermal spread angle; values for common materials; Example

- Diamond heat sinks

Chapter 4 - Convection Heat Transfer

- Definitions, Nomenclature

- Free or natural convection vs forced convection

- Heat transfer and film coefficients for air flow around different shapes

- Convection equations

- Effect of altitude

- Cooling fins and heat sinks

- PC board spacing, power, and heat removal; Example

- Forced convection on PC boards; Example

- Three methods of enhancing forced convection on PC boards

- Turbulent and laminar forced convection inside shrouded fins; effect of fin tip gaps

- Impingement cooling

- Interleaved fins

- Pin Fins plus impingement flow

-

Sample problems

- Natural convection

- Heat sink

- Laminar flow

- Turbulent Flow

-

Pressure Drop and Fans

- Equation for circular sections

- Fanning friction factor

- Cooling fan selection

- Pressure vs. airflow

- Pressure Drop Checks

- Pressure Head Basics

Chapter 5 - Radiation Heat Transfer

-

Fundamental Concepts

- Intensity

- Emission

- Irradiation

- Radiosity

- Blackbody Radiation

- Emissive power, σT4 tables

- Absorptivity

- Surface Reflectivity, Transmissivity

- Diffuse Gray Surfaces

- Radiation exchange between surfaces

- Radiation heat transfer equation

- Shape or view factor curves

-

Radiation Exchange

- Blackbody

- Diffuse Gray Surfaces

- Two-Surface Enclosure

- How to Reduce Temperature of Electronics?

Chapter 6 - Introduction to Thermal Resistance Networks

- Thermal Resistance Concept

- Conduction, Convection & Radiation Resistances

- Conduction Thermal Resistance

- Convection Thermal Resistance

- Radiation Thermal Resistance

- Thermal Contact and Interface Resistances

- Thermal Interface Materials

- Spreading Thermal Resistance

- Series Thermal Resistances

- Parallel Thermal Resistances

- General Resistance Network; Example

Chapter 7 - Evaluating Cooling Requirements and Heat Transfer Mechanisms

- Heat Sources and Temperature Ranges

- Fundamental Electrical Theory

- Defining Heat Sources and Temperature Ranges; Examples

- Heat Removal Mechanisms; Examples

Chapter 8 - Electronic Cooling Design Techniques: Components

-

Electronic Component Descriptions

- Discrete vs. Integrated Circuit

- Active vs. Passive

-

Component Packaging

- Lead Configurations

- Purposes of package configuration

- Component-to-PCB Mounting Methods

- Thermal Specifications of Component Packages

-

Junction-to-Ambient Thermal Resistance (qJA)

- Measurement Technique

- Measurement set-ups

- Junction-to-Case Thermal Resistance (qJC)

- Junction-to-Board Thermal Resistance (qJB)

- Parameters Affecting Thermal Performance

Chapter 9 - Electronic Cooling Design Techniques: Printed Circuit Boards

- Introduction to the PCB

-

PCB Types and Physical Characteristics

- Single- and Double-Sided PCBs

- Multilayer PCBs

- Method of Attaching Components

- PCB Design for Thermal Performance

- PCB-Chassis Mounting Methods

- Heat Sinking in Solid and Hollow Core PCBS – Example of Thermal Assessment

-

Thermal Design Concepts for Surface Mount Multilayer Boards

- IC Package Configurations

- Thermal Characteristics—Surface Mounted Piece Parts

- Pedestal and Via Hole Conduction

- Thermal Circuit Comparison

- Heat Exchange Fin Geometries

- Wedgelock Fastener Comparison

- Typical Digital Board—Solid and Hollow Core

- Hollow-Core Board Heat Exchange Study

Chapter 10 - Electronic Cooling Design Techniques: Chassis and Racks

- Chassis and Rack Designs

- Enclosure Packaging Examples

- Cooling Air Parameters

- Sample Electronics Cabinet Cooling Problem

- Pressure Drop in Electronic Cabinets

- Typical Electronics Enclosures

- Pressure v. Airflow Relationship for Various Enclosures

-

Fan Selection

- Internal Flow Considerations

- Design Discussion

- Relationships Among Heat Source, Heat Exchanger, and Cooling Air Stream

- Increasing Air Velocity Through the Heat Exchanger

- Determination of Cabinet Ventilation Area for Free Convection

- Buoyancy Pressure Formulas

- Discussion of Flow Resistance Coefficient; Sample Problem

- Typical Cooling Methods for Commercial Electronic Cabinets; Example

- Centrifugal Blowers

- Fan Characteristics

Chapter 11 - Special Cooling Applications

-

Advanced Cooling Techniques

- Boiling Dielectric Liquid System

- Thermal Electric Cooler

- Semi-Passive Thermosyphon

- Semi-Passive Falling Films

-

Simulated Electronic Chips in Dielectric Liquid

- Pool Boiling

- Flow Boiling

- Liquid Jet or Spray Cooling w/ Boiling

- Micro and Mini Channel Cooling: Simulated Electronic Chips with Attached Heat Sink

-

Introduction to Heat Pipes

- Why a heat pipe works

- Heat pipe sinks for electronic component cooling

- Fluid Compatibility

- Field experience

-

Constant-conductance heat pipe

- Types of groove and wick configurations

-

Diode heat pipe types

- Liquid trap

- Liquid blockage

- Gas blockage

- Variable-conductance heat pipes (VCHPs)

- Capillary pumped loop (CPL)

- Comparison of VCHP and CPL performance

-

Analysis: Heat pipe capacity

- System pressure drop

- Thermodynamic considerations

- Working fluids, compatibility

- Testing, applications, performance, references

- Experimental investigation of micro heat pipes fabricated in silicon wafers

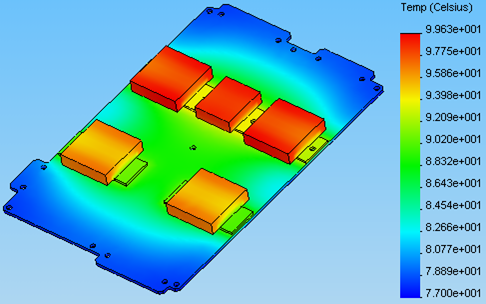

Chapter 12 - Thermal Modeling

-

Thermal Modeling Overview

- Why perform thermal modeling?

- Content and Level of modeling detail

- Modeling or testing? Or both?

-

Thermal Modeling Approaches

- Analytical Hand Calculation

-

Nodal Network and Thermal Resistance

- Basic Steps to Setting up a Nodal Network Model

- Thermal Modeling Examples

-

Finite Element (FEM) or Finite Difference Modeling

- Basic Steps to Setting up a Finite Element Model

- FEM Thermal Analysis Example

- General Steps in a Thermal Analysis

- Detailed thermal modeling example

- Commercial Thermal Modeling Software Packages

Chapter 13 - Thermal Testing

- Thermal Testing Overview

- Thermal Equipment

- Instrumentation

- Thermocouples

- RTDs

- Thermistors

- IR non-contact probes & cameras

- Liquid crystals

- Test Chambers and Systems

- Instrumentation

- Thermal Testing Fundamentals

- Electronic Cooling Testing Examples

Appendix D - Physical Properties of Materials

- Dimensionless Numbers

- Viscosities of Gases

- Prandtl Numbers of Gases near Atmospheric Pressure

- Specific Heats (Cp ) of Gases, Btu/lb-°F

- Physical Properties of Air, Steam, Oxygen and Water

- Thermal Conductivity of Metals and Alloys

- Thermal Conductivity (k) of Gases

- Properties of Metals and Alloys

- Physical Properties of Some Non-Metals

Appendix E - Conversion Factors

- Thermal Conductivity

- Coefficient of Heat Transfer

- Heat Flux

- Viscosity

- Length/Distance

- Energy/Power